The City of Pensacola updated its Transparent Pensacola page with documents and renderings. However, very few specifics about the hatchery.

There is audio of the Environmental Advisory Board of 02/26/14,

Three WEBY-AM Florida Sportsman Magazine Live! from early 2014,

Letters of support from Guy Harvey, Escambia BCC and University of West Florida,

A Studer Community Institute graphic,

Report of Council Action from June 20, 2011,

Planning Coordination Committee Meeting Minutes 1-27-15,

Project Scoping Meeting Agenda for 4-26-16, and

Technical Coordination Committee Meeting Minutes 6-3-15.

The most recent document the City posted is from April 2016, more than a year ago.

The document gives a few more details is the Technical Coordination Committee Meeting Minutes from June 3, 2015:

- Objectives of Pensacola hatchery:

- Official project title: Florida Gulf Coast Marine Fisheries Enhancement Center.

- Fisheries enhancement includes restoration and stocking of small fish raised at the facility. Large fish would have to be raised off-site at other facilities. Other elements of the hatchery include research and monitoring, as well as outreach and education.

- Building a wetland to filter nutrients, return clean water to the bay, and supply plants for future habitat restoration projects.

- Educational center will promote healthy coastal ecosystems like programs at Port Manatee facility.

- FWC hatcheries in Florida:

- Pensacola hatchery will be the first production-scale saltwater fish hatchery in Florida.

- FWC has operated a saltwater research hatchery in Manatee County for 25 years.

- Also two freshwater hatcheries, Blackwater River Fish Hatchery and Richloam Fish Hatchery.

- Facility property, conceptual site design, and essential project elements:

- Produce approximately 5 million 1-1.5 inch fish annually for stocking (Phase 1 fish) on the approximately 5.5-acre property.

- Presentation shows an image of the site and the tank farm next door. The property has some challenges related to coastal construction.

- Existing mitigation wetlands are nearby and details of new wetlands will be developed in the design phase.

- Conceptual site design includes indoor facility, stormwater ponds, storage pond for solids settling out, and treatment marsh.

- Small fish have a known tank size requirement; limited time to keep fish in the recirculating aquaculture system.

- Marsh and settlement ponds could be incorporated into the site usage with a boardwalk.

- Site historically featured a shipyard, African-American beach, and pool where locals learned to swim. Project will promote cultural heritage on signage/displays.

- Recirculating aquaculture system would feature broodstock rooms, temperature and light controlled conditions, and Phase 1 grow-out tanks where fish are raised for stocking.

- Proposed timeline:

- Presentation shows the proposed timeline for the project.

- Facility will be an architecturally favorable building, incorporating plans for the City.

- Federal projects have extra steps to go through, such as NEPA environmental compliance and other factors. Funds for this project are treated as Federal funds.

- Project activities accomplished to date and next steps:

- Environmental and cultural surveys have been done and the site has been cleared. For the last 20 to 30 years the site was used as a stockpile of soil and other materials. Geotechnical surveys of material have cleared it to be removed and disposed of in any appropriate manner.

- Next step is to bid surveys for material removal.

- Request for qualifications for design of site.

- Engaged geotechnical firm. Issuing statement of qualifications for architectural engineering firms. Will enter into contract in fall of 2015.

- Design of site and conceptual design alternatives. Once conceptual design agreed upon, will proceed with construction documents.

- Will bid construction within 12-18 months after construction bids.

- 2017-2018 construction.

Overview of Recirculating Aquaculture Systems

- Marine fisheries enhancement hatcheries are facilities that produce eggs, larvae, and juvenile fish that are released, and maintain broodstock (spawning adult fish) that represent the genetic diversity of wild fish.

- Recirculating aquaculture systems (RAS) use water treatment processes that sterilize wastewater for reuse. Reconditioning of water reduces water use.

- RAS are highly controlled aquaculture systems that raise a large number of fish in a small volume and have a small facility footprint, but are capital intensive.

- Why use RAS? Can support fish production on small tracts of valuable coastal land, or inland away from seawater due to their small water budget.

- Pond aquaculture fish are not tightly packed and ponds are more like the wild. Waste is flushed out of ponds continuously and diluted before discharging into the environment.

- Tank fish are concentrated. Water supply is small, sterilized, and recirculates > 80% of the water.

- Holding tanks and production tanks. Different sized tanks for broodstock, eggs, larvae, and juvenile fish.

- Waste removal: Round tanks with bottom-center drains concentrate waste. Fish waste includes solid waste, liquid waste (NH3), and gas waste (CO2).

- Temperature and oxygen are environmental variables that are monitored and adjusted.

- Round tanks “self-clean†and are well-mixed. Rotational current around tank (primary current) affects radial flow (secondary current). Radial current transports wastes to center drain. Rotational flow dependent on water pumping rate.

- Tank height and diameter ratio affects waste transport; about 3:1 height to diameter ratio is ideal. More fish produce more waste and need larger reconditioning systems. Amount of fish directs waste management plan. Waste removed continuously through mechanical pumping or biological removal, and solid waste filters that separate solids from water.

- Solid waste removal: Filters are efficient at removing particles from water. Foam fractionators can remove very small particles.

- Liquid waste removal: Fish produce ammonia (NH3) as liquid waste, which is toxic. Nitrifying bacteria use ammonia as food (nitrification).

- NH3 Ã NO2 Ã NO3

- NO3 is minimally toxic, used by marsh plants and anaerobic bacteria.

- Nitrifiers grow in water, but need surface to adhere to and need a “biological filter.†Vessel/tank biofilter packed with highly porous material for nitrifying bacteria to colonize.

- Gas waste (CO2) respired through gills, a fish metabolic end product. Negative effects on fish health if excess carbon dioxide acidifies the water. Forced gas ventilation of water with a “degassing box†increases gas exchange efficiency. Laminar flow passes water across trays and forces ambient air across the water and carries out the CO2.

- Pumps (0.25-5 horsepower) are required to transport water and wastes.

- High energy demand.

- One-phase power or three-phase power.

- Larger tanks with more fish require larger pumps, larger pipes, longer distance from tanks to filtration system, and more energy.

- Oxygenation is the first limiting factor in aquaculture. Concentrate oxygen into water. Pure O2 dissolving efficiency is key. Could add O2 with diffusers as emergency backup method.

- Temperature affects growth and spawning. Control can be through water or air. Locating chillers in an indoor room is ideal.

- Maintaining broodstock conditions for spawning (precision dependent on application).

- Monitoring and control: pH, CO2, power, temperature, and automated lights. In-tank sensors linked to a control center that relays information to a computer monitoring and alert system. Easy access to cables and wires of the controls is important.

- Monitoring, alarming, and control can be staffing, technology, or software programs developed specific to the facility.

- Facilities in Recirculating Aquaculture Enhancement Hatchery:

- Footprints in the facility will include tanks for broodstock, eggs, larvae, and juveniles. Also a holding tank for juveniles from the time they are larval cultured to when they are released.

- Broodstock need a large facility footprint, large tanks for large fish (adult redfish 30 lbs.) with the appropriate filtration of waste and reconditioning of water. Broodstock need excellent water quality, and precise control of temperature and lighting like the natural cycle for spawning.

- Red drum have a 3-4 month period of spawning, so we time that with the phasing of the fish for release (Phase 1).

- Egg collection system: Separate egg collection tank where eggs pass into a fine mesh basket and are moved to an incubation system. Incubation systems should be easily accessible from the broodstock systems. Need secure access to egg hatching facility to reduce pathogens from foot traffic.

- Egg hatching in separate tanks (incubators) for sanitation and health of larvae. Small tanks with large numbers of eggs. High flow rate water filters to flush out solid waste. Sterilization and temperature control are important.

- Larval culture facilities: The larval stage is the most delicate life stage in the hatchery. Low biomass because susceptible to high turbulence. Production in medium to large tanks. Temperature and light control affect development. Live feeds (zooplankton) are cultured on site.

- Juvenile facility is the largest footprint for a hatchery and the Pensacola hatchery is not suited to it because of the size of the property. Additional hatcheries in the future will need to consider the size of facilities when putting large numbers of fish in a small area.

- A large amount of O2 is critical to produce juvenile fish. High tech filtration works 24 hours a day. Largest water source, largest biomass, and largest amount of waste.

- Cohorts of fish (batches) are the same in each phase. Increase tank size with fish growth.

- Wastewater management plan for tanks and also for discharge.

- Solids, nitrogen, and approved chemicals for parasite removal if necessary.

- Redfish tolerant of parasites; can be removed by a freshwater bath.

- Solids removed from effluent by ponds or tanks used to settle waste to the bottom or filtration systems that use concentration and remove waste to a drying area, then to a landfill.

- For removing nitrate: 1) anaerobic bacteria nitrification, 2) marsh plants are a proven method with environmental benefits, or 3) sewer for specific small volume discharges only; depends on city, county and state permits required. An injection well is not a preferred method.

- Summary:

- Seawater has to have a treatment plan.

- Has to be high-quality, sterilized.

- RAS key factors are reduction of water use and reconditioning of water use.

- High amount of control of processes for RAS.

- Facility needs unique systems for each production stage.

- Waste management plan.

- Experience with recirculating systems has been taking the pond based setup and slowly transitioning to RAS framework over many years. It will be nice to build a new RAS facility from the ground up. The design will be complex, built to latest specs, and flexible enough to add new technology.

The photos are of the visitors’ area and exterior, but none of the fish hatchery component:

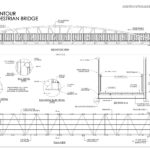

The renderings show a walkway and a bridge to BDI building but no dimensions of the buildings or rooms. No layout of the hatchery or tank farm. For what is supposed to be a “complex design, built to latest specs, and flexible enough to add new technology,” these are very simple renderings – except for maybe the bridge.

This is classic Ashton Hayward – giving the public a bunch of documents and hoping no one will read them–but offering few specific details about the project.